已有账号登录账号

Embracing Industry 4.0, Taijing Electronics Joins Hands with Saiyi Information to Build an Intelligent Factory

Taiwan Jingji Co., Ltd. (referred to as "Taijing Electronics") was established in 1983, specializing in frequency and sensing components. Its headquarters are in Taipei and it has manufacturing factories in Ningbo and Chongqing. In the passive component industry, Taijing Electronics has been at the forefront of the global rankings in the quartz crystal oscillator field for many years, and has always been committed to the research and development, design, production, and sales of quartz crystal phase resonators, oscillators, optical sensors, automotive electronics, and other products, closely adhering to market applications and demands. Passive components, as one of the most versatile electronic components in the semiconductor industry, have maintained a stable growth rate in response to terminal demand upgrades for many years. Through independent core technology, Taijing Electronics has successfully developed various sensing components, which are widely used in communication, wearable devices, the Internet of Things, server storage devices, automotive, telecommunications, medical and other markets.

The era of "Industry 4.0" drives the construction of intelligent factories

In the past 30 years of development, the pace of Taijing Electronics' own informatization has never stopped. However, with the advent of the "Industry 4.0" era in recent years, facing challenges such as intensified market competition, tight order delivery times, improved production efficiency, increasing labor costs year by year, and product quality control, the construction of intelligent factories has become extremely urgent. There is an urgent need for a rigorous, stable, open, platformized, and technologically forward-looking intelligent manufacturing platform software, Instead of a traditional barcode data collection system or a production management system based on ordinary ERP software, to address new business challenges. So in 2018, after multiple evaluations, Taijing finally decided to collaborate with Saiyi Information to solve the corresponding key business problems.

Join hands with Saiyi to jointly build an intelligent chemical factory

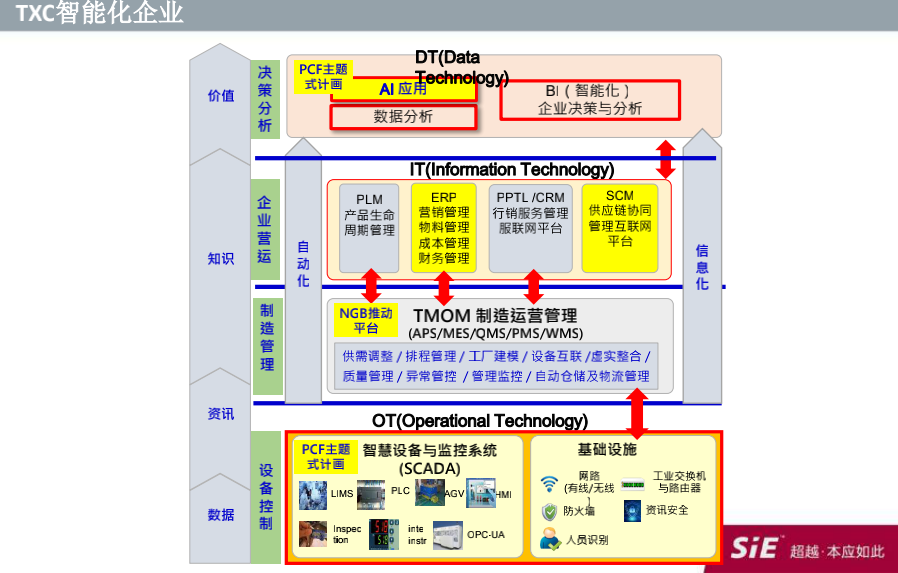

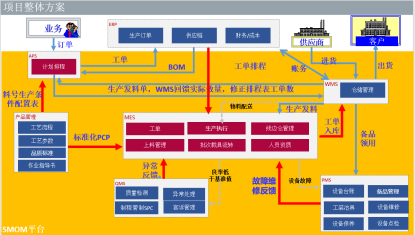

At the beginning of 2018, the implementation of the Taijing Electronics TXC Intelligent Factory project began. After comprehensive evaluation and multiple inspections in the early stage, Saiyi Information proposes digital improvements from four aspects: enterprise decision-making analysis, enterprise operation, manufacturing management, and equipment control to address issues such as the impact of various engineers on work quality and efficiency when dealing with different systems, insufficient efficiency in equipment exception handling and maintenance, more efficient connection between procurement and order production, and timely judgment of abnormal orders, Connecting the information flow gap between the upper level plan and the lower level equipment control, the information flow, financial flow, and control flow are coordinated, providing strong data support for production big data analysis, improving production management methods, achieving transparent production, and helping Taijing Electronics achieve the goal of an intelligent factory faster.

Drive innovation in the company's process system by building an "intelligent factory". Introduce the Saiyi Manufacturing Operations Management Platform SMOM into the project to achieve intelligent management of digital workshops, and integrate and collaborate with upstream and downstream software (PLM, ERP, etc.) of the group, enabling all factory areas and production lines of the group to use the same set of system standards.

Taijing Electronics has put forward requirements for standardizing, integrating, and collaborating various software systems in the past, hoping to establish a universal main framework. The SMOM (SIE Manufacturing Operations Management) system independently developed by Saiyi Information is a further extension of MES, which includes five aspects: planning and scheduling, production and manufacturing management, quality management, equipment management, and warehouse management, Jointly serving the entire manufacturing operation process of the enterprise can precisely meet the overall goal of Taijing to build a TXC intelligent factory through integrated systems. At the same time, Saiyi Information also suggests that Taijing improve its EMS environmental system/VDA6.3 system/IATF16949 system, and incorporate international standards such as SPC, PAT, and SYA regulations into the project implementation to achieve the goal of sharing a manufacturing operation management system (T-MOM).

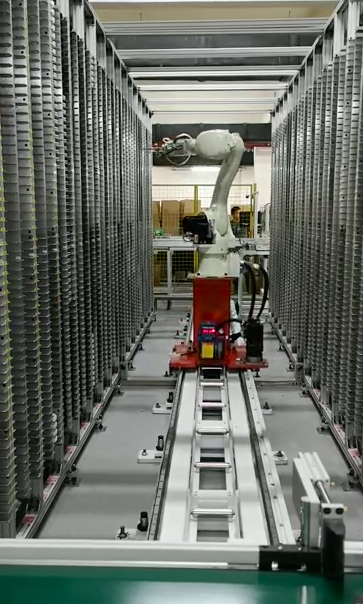

At the same time, Saiyi Information has also used the SWMS (Warehouse Management System) in SMOM products to create an intelligent three-dimensional warehouse system for Taijing Electronics, which integrates shelves, loading machines, handling robots, automatic labeling systems, data collection systems, and management systems to achieve automated access and simplified operation of three-dimensional warehouses. Goods are placed on and off shelves, achieving fully intelligent automatic allocation of storage space based on first in, first out, to avoid human error, and 100% error prevention when leaving the warehouse. At the same time, it also reduces marking errors, mixed materials during shipment, eliminates the phenomenon of abnormal materials entering the warehouse in violation of regulations, reduces the problem of obsolete materials in inventory, and improves inventory utilization by more than 10%.

The results are remarkable, and the intelligent effect is immediate

The Taijing Electronic Digital Intelligent Chemical Plant project takes "first intelligent people, then intelligent" as the principle for preliminary preparation, and has done a lot of internal mobilization work to work together, implement in stages, and complete the project in a step-by-step, efficient and fast manner. With the joint efforts of Taijing and Saiyi Information, the establishment of TXC intelligent factory has achieved the following benefits:

Transparency - Widely used industrial software such as SMES (Manufacturing Execution System), SAPS (Advanced Production Scheduling), SEDO equipment management, SQMS quality management, SWMS warehouse logistics management, etc., to achieve visualization and transparency of production sites, and to analyze the causes of quality problems through software such as SPC (Statistical Process Control).

Rigorous - Under the concept of lean production, it is possible to achieve order driven, pull based production, minimize inventory of work in progress, and eliminate waste. Standardization, modularization, and serialization lay the foundation for promoting lean production.

Simplicity - Continuously improving the automation level of production, testing, and factory logistics by combining the product and production characteristics of the enterprise. The combination of human-machine, intelligent manufacturing units, and assistance equipment greatly reduces the labor intensity of employees.

Intelligence - from the issuance of production scheduling instructions to the feedback of completion information, achieving closed-loop. By establishing a production command system, real-time insight into the factory's production, quality, energy consumption, and equipment status information can be gained to avoid unplanned downtime. By establishing a digital twin in the factory, it is convenient to gain insight into the status of the production site and assist managers at all levels in making correct decisions.

Efficiency - Saiyi Information assisted Taijing Electronics in creating a warehouse system, which achieved fully automated, visualized, and traceable warehouse management throughout the entire process through process improvement and automation equipment import based on the SWMS system schedule, saving manpower and improving efficiency.

Riding the Wind and Waves to Build a Smart Future

As a professional frequency component manufacturing enterprise, Taijing Electronics continues to adapt to market demand and enhance its competitiveness. In the process of digital transformation, Taijing Electronics has joined hands with Saiyi Information to introduce SMOM system, promoting continuous improvement of technology and products through digital management, and adding more support to its further development in the passive component industry. In two years of in-depth cooperation, Saiyi Information has continuously improved the technology and process of the TXC intelligent factory, successfully creating a TMOM system belonging to Taijing Electronics, and completing the transformation of the intelligent factory.

Whether it's Industry 4.0 or Made in China 2025, the key is information reengineering. The digitalization driven full value chain management model will be the main direction to enhance industry competitiveness. For Taijing Electronics, the two phases of intelligent factory projects in cooperation with Saiyi Information are an important step towards its strategic transformation towards "intelligent manufacturing", making it more competitive in the global passive component industry competition. As an enabler of enterprise digitalization and intelligence, after 15 years of development, Saiyi Information has successfully provided enterprise digitalization solutions and consulting implementation services to over 1000 well-known leading enterprises in the industry, accumulating a large number of enterprise application scenarios, and gradually developing into a high-end market share leader in the domestic intelligent manufacturing field. In the wave of digital reform, the market belongs to the brave ones who dare to break through. In the future, Saiyi Information will continue to ride the wind and waves with Taijing Electronics, and build the future intelligently.